Technology

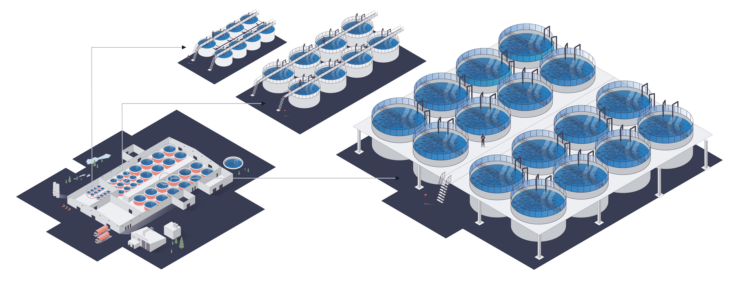

Land-based salmon production using RAS (Recirculation Aqua System) technology.

We are building state of the art RAS facilities together with the best in the industry.

In our deployment of the system, water from the canal is pumped through filters and a water cleaning facility before being poured into the fish tanks. Some of the fresh water used in the smolt phase will then be used in a greenhouse to produce salad. The rest will be cleaned and re-used.

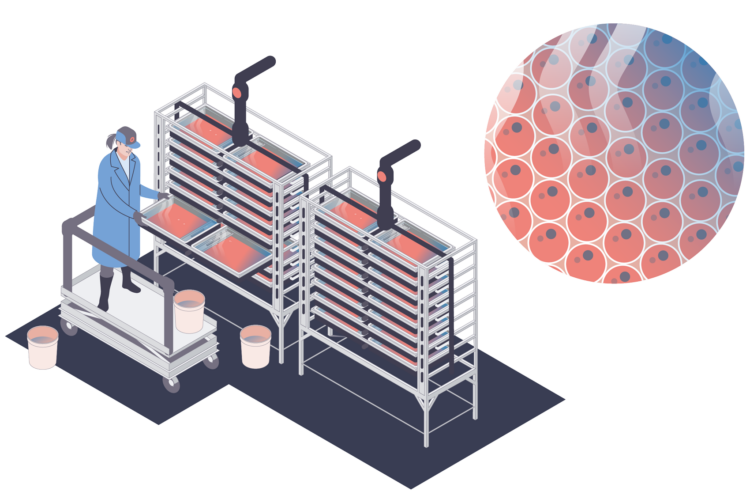

Eggs and hatchery

Columbi Salmon will buy fish eggs (ova) from an external supplier. The eggs are contained in shelves where temperate freshwater flows through the shelves.

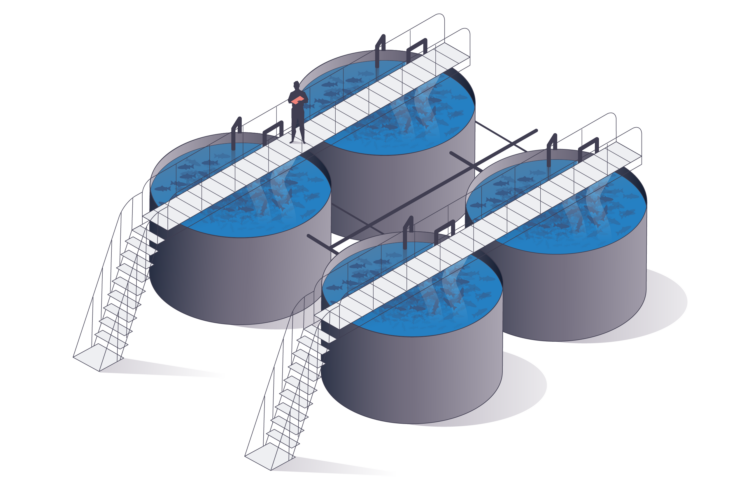

Tanks for small fish

After hatching, the fish is moved to tanks, where they remain in fresh water until reaching 100-300 grams. In this phase, the smallest fish are called fingerlings,while the larger fish are referred to as smolt.

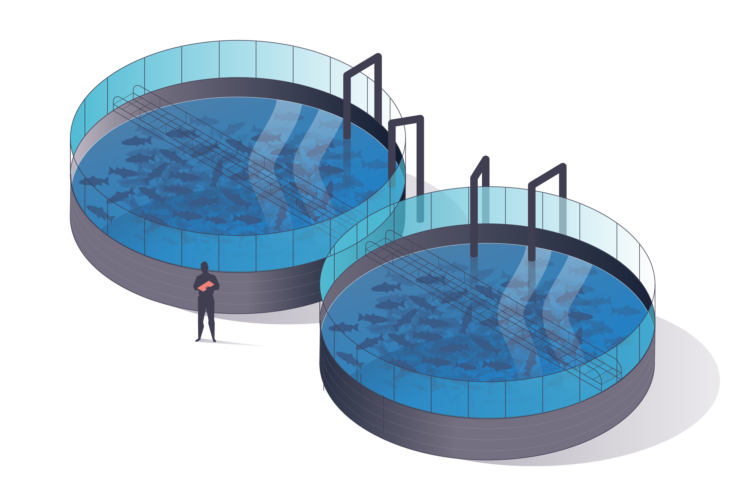

Grow-out stage

The grow-out stage corresponds to the period when the fish in traditional farming are moved from fresh water on-shore, to the ocean. Meanwhile, in our system the fish are transferred to the largest grow-out tanks.

Brackish water from the canal is pumped into large tanks and 99.9% of the water is re-circulated in a recirculating aquaculture system with various filters. The residual sludge and feed waste are removed and used in the production of biogas.

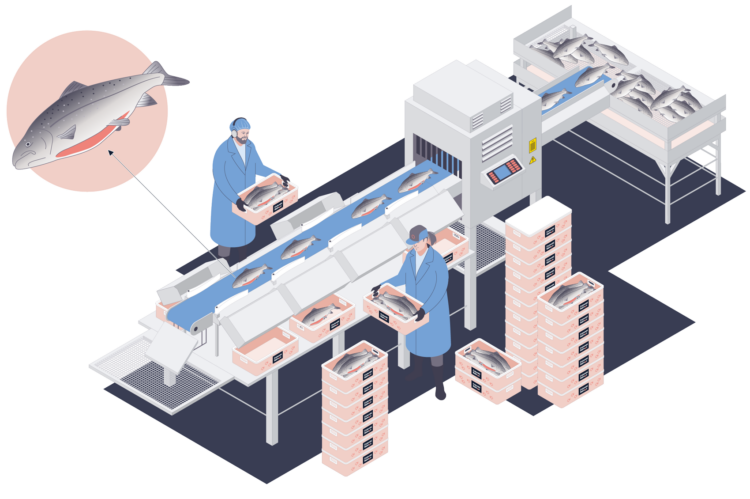

Primary processing

When the fish reaches its target weight (4-5 kilos), it is transferred to the primary processing plant, which is situated next to the largest grow out tanks. The fish is slaughtered, and gutted salmon, including the head, is packed in boxes, chilled and transported to consumers.